Nissan has released a video giving us an insight into how the magnificent twin-turbo VR38 engine in the GT-R is built.

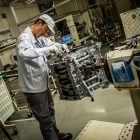

Only four master craftsmen, known as takumi in Japan, at Nissan’s Yokohama factory are sanctioned to build the engine for Nissan’s halo model in a clean room.

GT-R owners will find the name of one of these four artisans on the engine of their cars – Izumi Shioya, Nobumitsu Gozu, Tsunemi Oyama and leader Takumi Kurosawa. Together, they have over 100 years of combined experience.

Kurosawa, whose first name shares the same pronunciation as his team of craftsmen, makes street GT-R engines as well as Super GT300 racing version. He and his team put together some 374 components that make up the engine in about six hours. Once the 404kW engine is completed and has undergone inspection, the craftsmen install a named plague as a “pledge of quality.”

“By putting my name on the engine block, I strongly feel I represent Nissan and am regarded as a builder of GT-R engines,” says Kurosawa. “I feel a strong pride.”

“If you just want to assemble GT-R engines, any skilled person can learn in three to four months, but GT-Rs are used for shopping or to drive at speeds of 320km/h on a racing circuit, so exact precision for each engine part is required.”

ForceGT.com Car News, Car Reviews, Video Reviews, Tuning and much more.

ForceGT.com Car News, Car Reviews, Video Reviews, Tuning and much more.